The wiring harness is the central network of an automobile’s electrical system.

Without the wiring harness, the vehicle’s electrical circuit wouldn’t exist. The wiring harness refers to a set of bundled components designed for connecting the electrical circuit. These components are made of copper contact terminals (connectors) that are crimped to wires and cables and then encased with insulation or a metal shell. Automobile wiring harness testing includes environmental testing, electrical performance testing, and mechanical performance testing of the wiring harness.

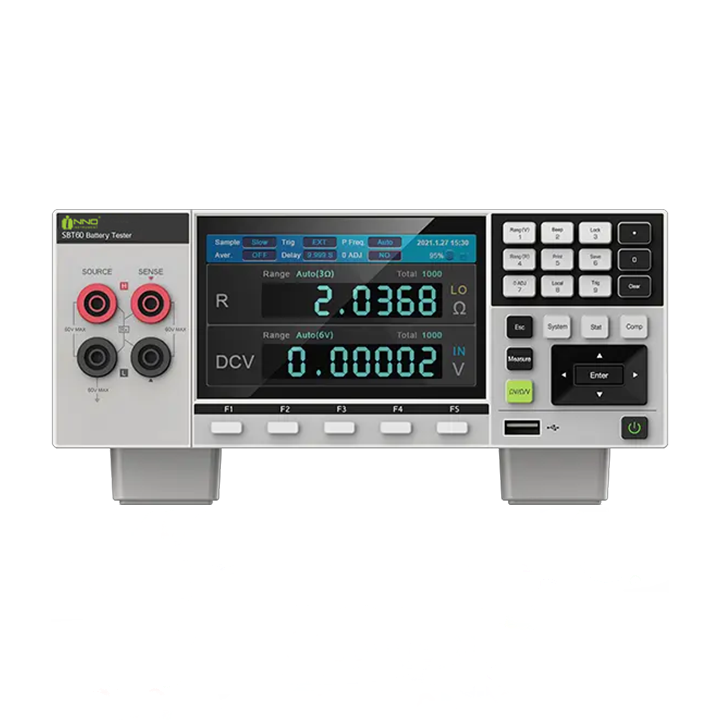

Since its inception, the automobile industry has gone through a lot of advancements and become more and more electrified and intelligent, which has subsequently provided substantial opportunities for the evolution of automobile wiring harnesses. Just like the nerves and blood vessels in the human body, automobile wiring harnesses serve to interconnect various components of a vehicle. Therefore, the reliability of wiring harnesses has become a crucial indicator of automobile performance. SUITA Electric’s SBT60/300 battery tester is a high-precision, high-resolution instrument for battery resistance testing. It finds wide application in measuring the resistance of various batteries, including lithium batteries for mobile phones, storage batteries, power batteries, and static crimp resistance in automobile wiring harnesses. It employs the AC four-terminal testing method, enabling more accurate testing of battery’s internal resistance and voltage.

Main Advantages

INNO's strong professional capabilities make its products more advantageous in related fields

voltage ±0.01%rdg ±3dgt; resistance ±0.4%rdg ±5dgt

voltage measurement up to 300V; resistance measurement 3mΩ - 3000Ω