How INNO Fiber Cleavers Help Users Maintain Precision and Diagnose Cleave Quality Issues

At INNO, our goal is simple: to make fibre work more predictable, more efficient, and easier to manage, regardless of a user’s level of experience. Field conditions are rarely perfect, and challenges are a natural part of everyday fibre installation and maintenance. That is why INNO devices are designed not only for precision, but also to actively support users in diagnosing issues and maintaining consistent performance.

Clear Cleave Quality Diagnostics in INNO Fiber Cleavers

A fusion splice is only as good as the fibre preparation that comes before it. During field work, variations in temperature, dust, handling, and workload can all affect cleave quality. These are typical, real-world conditions, not technical faults of the equipment.

INNO fusion splicers continuously monitor the splicing process and clearly inform the user about the type of issue detected. Messages such as right fiber core shape wrong, left fiber place error, or fiber endface gap wrong provide immediate insight into what part of the process may need attention. This allows the user to analyse whether the issue is related to fibre placement, cleave quality, or preparation, rather than relying on trial and error.

Thanks to this approach, even less experienced technicians can quickly narrow down the cause of repeated splice warnings and take appropriate action.

Identifying Cleave Quality Issues and Blade Wear in the Field

When cleave-related warnings appear frequently, it is often worth looking one step earlier in the workflow. Repeated messages linked to fibre endface or core shape may indicate that the fibre is not being cut optimally. In such cases, common causes include a worn cleaver blade or incorrect blade height settings.

INNO systems are designed to help users recognise these patterns. If your fusion splicer is synchronised with View Pro Manager, recurring cleave-related errors can trigger notifications suggesting that blade replacement may be required. This proactive feedback helps prevent unnecessary downtime and reduces the risk of increased splice loss over time.

Identifying Cleave Quality Issues and Blade Wear in the Field

Not every issue needs to be solved alone in the field. If you are unsure about the root cause of a problem, INNO makes it easy to get support. A simple screenshot from the fusion splicer screen can be sent directly to our service centre, where our technical team will help analyse the issue and guide you toward the correct solution. This support structure ensures that users always have access to expert knowledge when they need it.

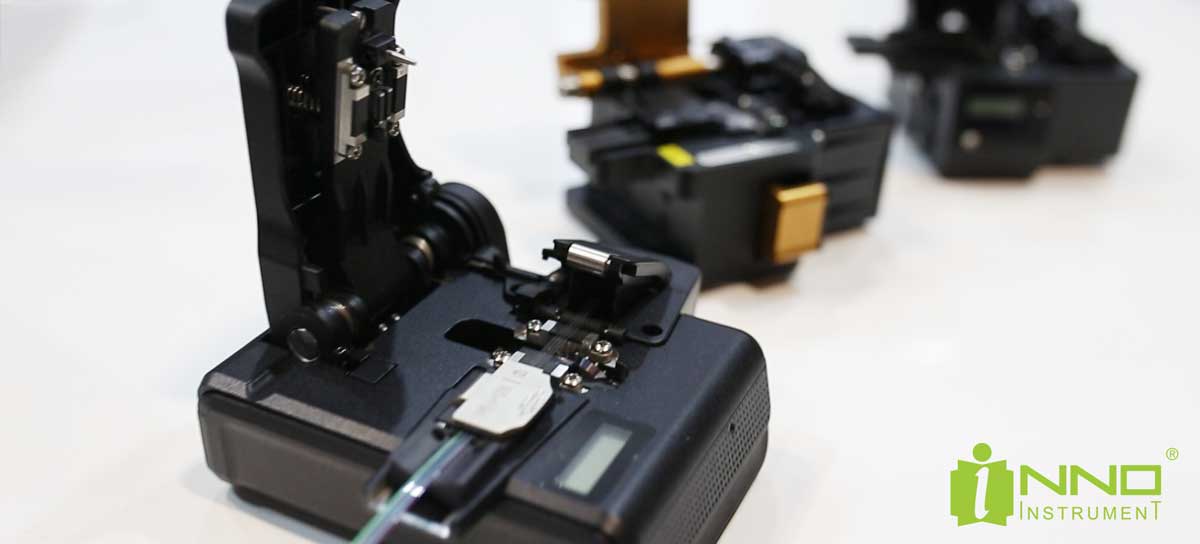

Fiber Cleaver Blade Design for Long-Term Precision and Consistent Cleaves

INNO fibre cleaver blades are engineered for durability and predictable performance. Each blade has a total lifespan of up to 60,000 fibre cleaves, based on 24 rotation points, with up to 2,500 cleaves per position. The blade rotation system ensures even wear across the blade surface, rather than concentrating stress in a single point. This design supports stable cleave angles over time and helps maintain consistent splice quality throughout the blade’s service life.

Original INNO Fiber Cleaver Blades and Professional Calibration Services

If you determine that a new blade is required, you can purchase an original replacement blade directly from INNO. Using only genuine INNO parts is essential to maintain the highest level of performance, accuracy, and long-term reliability of your equipment.

Alternatively, you can contact our authorised service centre to arrange professional blade replacement combined with full fibre cleaver calibration. This option ensures that the cleaver is returned to optimal working condition, with all settings verified and adjusted according to factory specifications.

How Precise Fiber Cleaving Helps Reduce Splice Loss and Improve Network Reliability

Accurate fibre preparation is one of the most effective ways to minimise splice loss and maintain network reliability. By combining clear diagnostic messages, smart software integration, durable mechanical design, original spare parts, and direct access to technical support, INNO helps users maintain the highest level of precision in everyday field work.

With INNO, you are not left guessing. You are supported at every stage of your workflow, so your equipment continues to deliver consistent, reliable results in real field conditions.