INNO Instrument’s I4S fusion splicer has recently undergone rigorous testing under extreme conditions to assess its performance in high-altitude environments. These tests were conducted by Telmark Supply S.A.C. in Abra de Anticona, also known as Ticlio, located in the Huarochirí Province of Lima, Peru. Ticlio, standing at an altitude of 4818 meters above sea level, is known for its harsh weather conditions, making it an ideal location to challenge the I4S splicer’s capabilities.

Objective of the Test

The primary objective of this test was to evaluate the operational performance of the I4S fusion splicer under high-altitude conditions, specifically focusing on its ability to maintain efficiency and accuracy despite potential environmental challenges. These challenges included low temperatures ranging from -3°C to 7°C and wind speeds reaching up to 4.1 m/s.

Background of the INNO I4S Fusion Splicer

The INNO I4S fusion splicer is designed with portability and advanced functionality in mind. It features a 5-inch high-resolution LCD touchscreen with an intuitive graphical user interface (GUI), offering users clear and large fiber images with up to 320X zoom. The splicer is equipped with a fast fusion mode that completes splices in just 4 seconds and a heating time of 9 seconds, with a single battery capable of handling up to 400 splicing cycles.

The device is engineered to operate efficiently at altitudes up to 5000 meters, under relative humidity between 0% to 95%, and in temperatures ranging from -10°C to 50°C.

Test Setup and Methodology

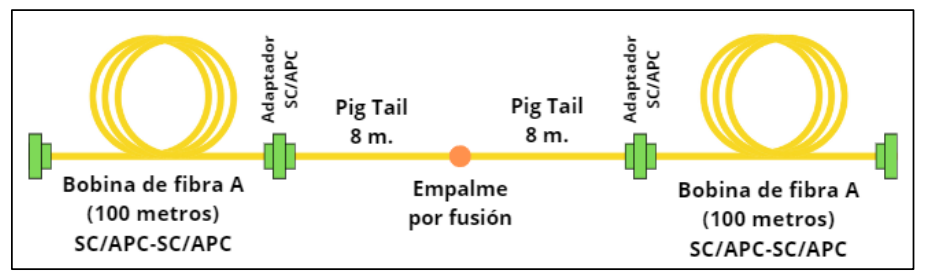

The test was conducted on August 8, 2024, over a three-hour period. The setup included the I4S fusion splicer, two 100-meter fiber reels with SC/APC connectors, two 8-meter pigtail SC/APC connectors, and two simplex SC/APC adapters. The optical time-domain reflectometer (OTDR) was used to measure the attenuation of the splices.

The network model for the test comprised two fiber optic reels connected by a single fusion splice, performed by the I4S fusion splicer. The quality of the splices was evaluated based on ITU-T recommendations G.650.3 and L.12/L.400, with a focus on achieving a maximum attenuation of ≤0.1 dB.

Test Results

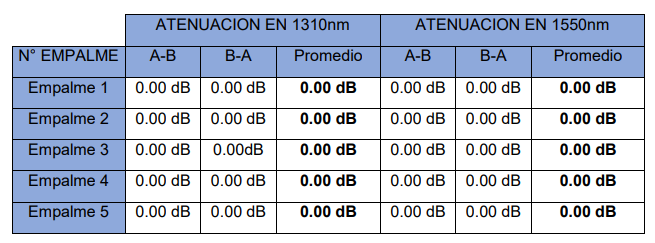

The I4S fusion splicer successfully completed the splicing process under extreme conditions without the need for arc calibration. A total of five splices were performed and tested bidirectionally at wavelengths of 1310 nm and 1550 nm using the OTDR=.

Remarkably, the splices exhibited no measurable loss, achieving 0.00 dB attenuation in both directions across all tested wavelengths, which is a testament to the splicer’s outstanding performance.

Conclusions

The INNO I4S fusion splicer demonstrated exceptional reliability and performance under harsh environmental conditions. Despite the challenges of high altitude, cold temperatures, and wind, the splicer consistently produced high-quality splices with zero attenuation loss. This performance highlights the I4S as an ideal choice for fiber optic projects in extreme conditions, offering both portability and precision.

Acknowledgment

We extend our gratitude to Telmark Supply S.A.C. for their dedication and expertise in conducting these critical performance tests. Their work has been invaluable in showcasing the capabilities of the INNO I4S fusion splicer. For those interested in a more detailed analysis, the full test report is available for download in PDF format.